You don’t need to know your production cost to manage futures risk. You do need to know your trucking cost in fine detail to be a great merchandiser.

Every time we teach a class or speak to a group WE learn something. I’m not kidding, it is every time we are out if we are doing our job as a good listener. One question we ask when we are working with a client on a farm is do you know the fixed and variable cost of the trucks you own? We also ask do you know the commercial rates from your farm to the delivery markets. If you are starting to get a bit of a complex don’t worry we work with some very well managed farms and have yet to have one provide a passing grade answer. The good news is this is a data problem. Data problems can be solved.

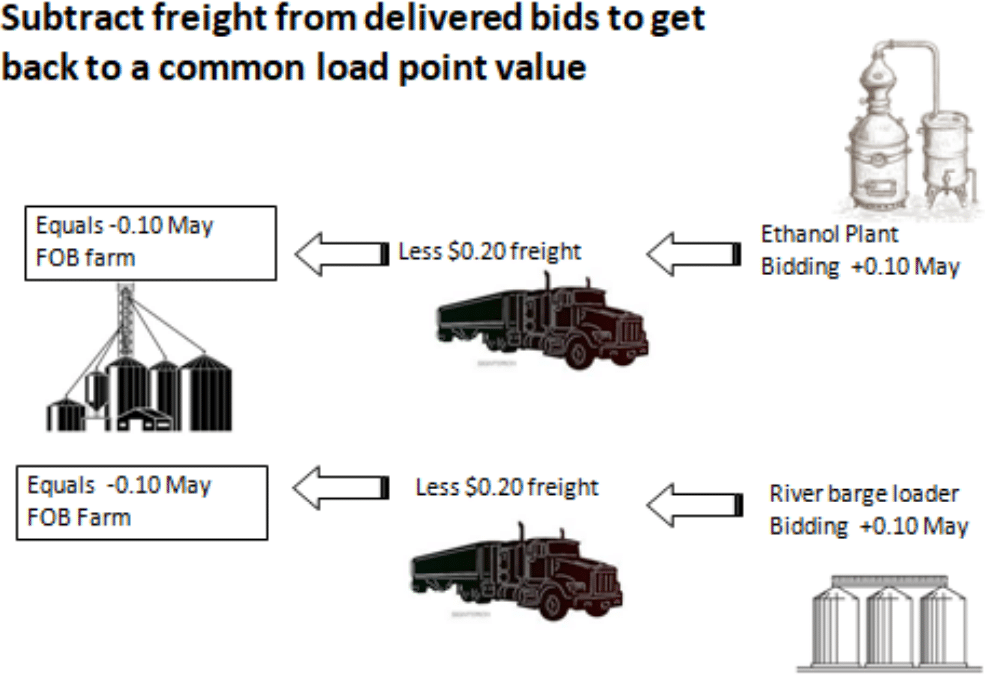

First, why is knowing freight cost so important? The obvious answer is to bring a buyer’s bids back to the load point. We need a common denominator to compare. You want to know what the value is FOB (free on board) the bin or the field edge as an example. Since we now only get bids only as a basis to eliminate the futures noise we now can easily subtract freight to get this back to the load point. (differences in unload speed or grading are considered part of of the basis bid from the buyer)

In this example everything else equal we are agnostic to deliver to either location. In reality there are always reasons such as unload speed, grading, payment, ect that can make a difference.

Now let’s complicate matters. Most farms that own truck(s) want to haul their own grain. After all it tends to be in the less busy season for labor and the trucks are sitting idle. This may be the correct answer but we want the data to back it up.

- When we look at truck ownership costs a great deal of them are variable. Variable meaning the cost does not occur if the truck is sitting still. Fuel, oil, tires, and even depreciation tend to be miles based expenses. Insurance is actually one of the bigger fixed expenses. Some may say labor is fixed if the workforce is year round employed with no better alternative. The reason you want to know your cost broken into fixed and variable is to make sure you are creating positive cash flow. If you can’t cover your variable cost you are actually destroying value.

- Let’s challenge ourselves to the value of that driver’s time. We use the benchmark amongst my friends of $100/hour. Maybe with inflation that should be $150/hour. Mind you my friends will chastise me if I’m doing something I like such as cutting firewood because I’m not meeting my earnings target. As a manager of a modern farming operation there is a never ending list of jobs that pay $100/hour. (Think taking a class in merchandising skills). I then get the push back that the mobile phone and a headset let one multitask. Are you REALLY able to dig into some data or shake hands with a potential landlord? The high dollar jobs take focus.

Now you have done some digging and have a good sense of what it costs you to load, haul, and unload in cents/mile. That’s a great starting point for “winning in the details”. We have an anchor point to start making money.

How many of you ask your buyers if they will bid grain picked up? How many get a quote from a commercial trucking company or even your neighbor?

As a buyer of grain here are some reasons I would quote you a freight rate lower than you could do it yourself.

- I have some dedicated carriers that I have negotiated aggressive rates with in exchange for a steady volume of hauling. These carriers are able to drive down fixed costs by spreading them out over more miles.

- I have my own fleet of trucks and drivers that are very much a fixed cost and any return over variable helps offset the cost coming no matter what.

(fixed) - Arbitrage, a fancy French word that means optionality. Some buyers will buy the grain FOB the farm but won’t decide where it goes until loading time. They stand to make money by moving grain to the best net market. This could be significantly out of your normal markets if some anomaly takes place in bidding or a freight opportunity arises.

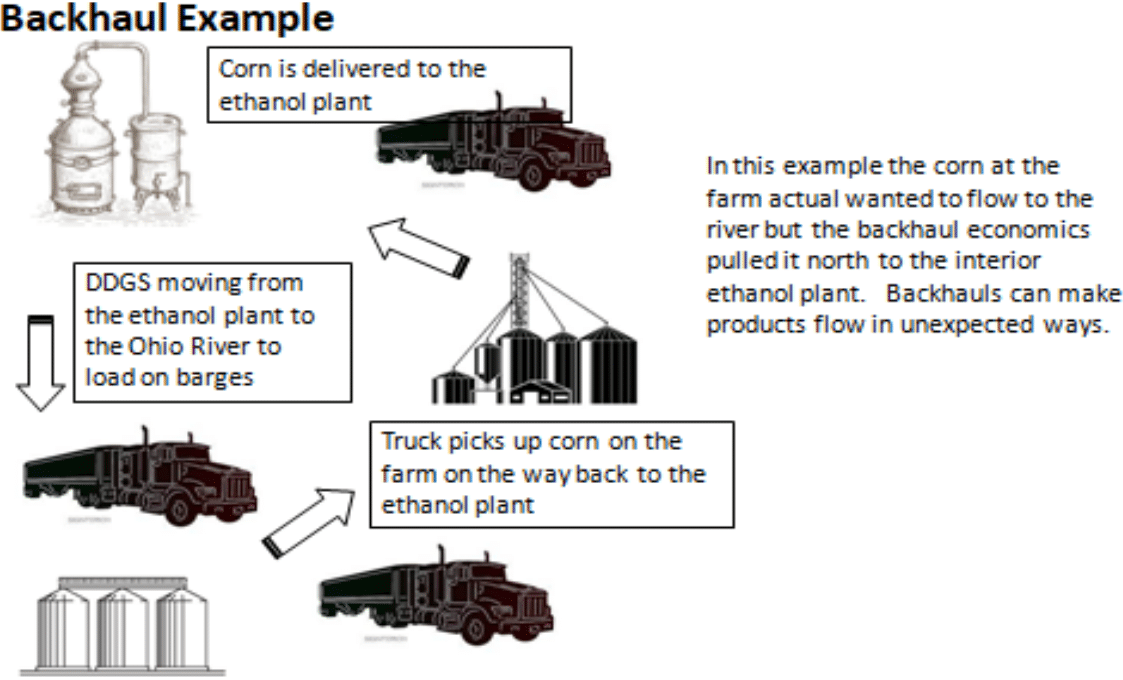

- Backhaul- Commercial trucks are always hunting backhauls. This is not something a farmer would necessarily be aware of or invited to know.

Example: This is a backhaul flow that is happening today in south west Ohio.

The moral of this story is you have to know your own cost. Once you are working from data it is time to leverage your knowledge. It’s cheap to get on the phone and get freight quotes. Don’t be afraid after getting a buyer’s best delivered bid and then ask them to rebid the grain picked up. Great merchants are always pushing and prodding on freight rates.

One last point that connects this blog with my previous blog on carrying cost is speed. Today it is costing me 5+ cents per bushel a month to carry corn. Even if commercial trucking is more expensive, what if we can deliver the grain two months faster. Supplementing your own trucking capacity might be the optimum solution. Now we have cash in hand quicker. Our risk of shrink in the bin is eliminated. We can focus on higher value work.

Closing this blog out I am not saying you should not haul your own grain. As long term buyers we know there are opportunities out there that you can take advantage of by applying ever greater amounts of knowledge.

“win in the details”

“cents per bushel matter”

Jeff Kazin

AgrisAcademy

jkazin@agrisacademy.com